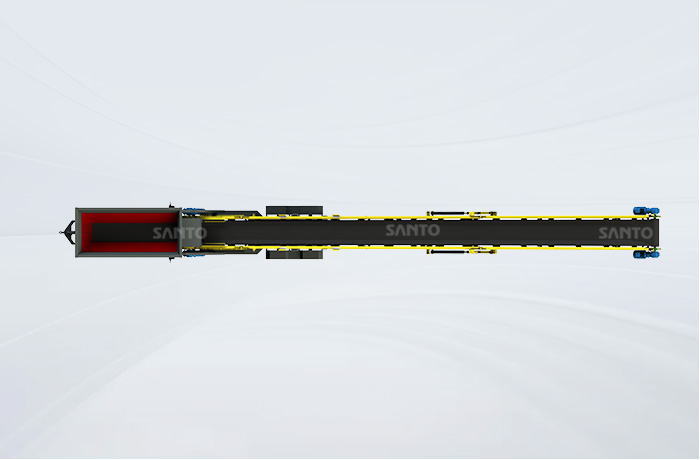

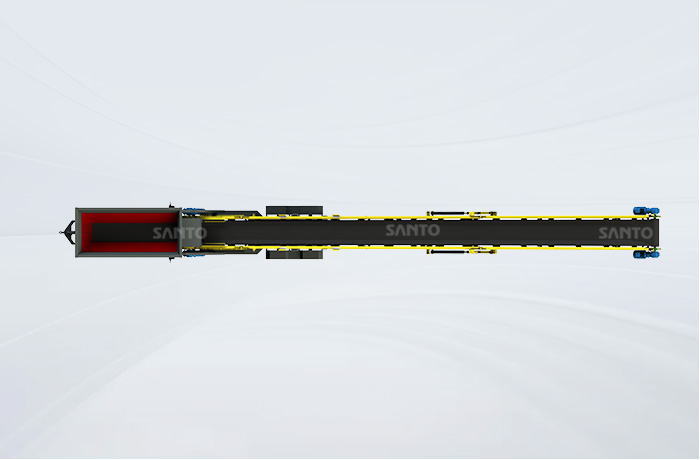

Wheeled Feeder mobile stacker is mainly designed for a range of applications like loading, unloading, feeding and transferring bulk materials, effectively eliminates the need to have both a separate hopper feed unit and a stacker unit. As with all Santo’s other mobile conveyors, the feeder wheeled stacker series can be customized to suit the client’s specific requirements.

Specifically designed hopper improves material flow eliminating bridging and ensures efficient movement of materials.

Folds/Lowers hydraulically for transport, cost effective transport around the globe.

The use of hybrid technology includes an onboard electric motor that provides the flexibility to run the equipment from an external power source or the standard onboard engine.

The wheeled unit provides excellent mobility on site.

Specifically designed hopper improves material flow eliminating bridging and ensures efficient movement of materials.

Folds/Lowers hydraulically for transport, cost effective transport around the globe.

The use of hybrid technology includes an onboard electric motor that provides the flexibility to run the equipment from an external power source or the standard onboard engine.

The wheeled unit provides excellent mobility on site.

Range of designs and hopper capacities depending on feeding equipment and production rates on site.

Variable speed belt feeder to ensure efficient material transfer from hopper to discharge conveyor.

Directly discharge from wheel loaders, grab cranes or excavators, and eliminates the double handling of material on site.

Santo feeder wheeled mobile conveyors can move a wide range of bulk materials, including:

|

Model |

Belt Width (mm) |

Length (m) |

Discharging Height (m) |

Stockpile Volume(m3) |

Capacity(T/H) |

Weight(T) |

|

WHF1015 |

1000(39.3inch) |

15 (50ft) |

7.0 (22.9ft) |

559.6 |

500 |

13 |

|

WHF1020 |

1000(39.3inch) |

20(65ft) |

8.9(29.2ft) |

1181.2 |

500 |

14 |

|

WHF1215 |

1200(47.2inch) |

15 (50ft) |

7.2 (22.9ft) |

559.6 |

700 |

15 |

|

WHF1220 |

1200(47.2inch) |

20 (65ft) |

8.9(29.2ft) |

1181.2 |

700 |

16 |

Our factory area( ㎡ )

More than 30 R&D and design engineers

More than 120 workers

Serving more than 60 countries and regions.

Our factory area( ㎡ )

More than 30 R&D and design engineers

More than 120 workers

Serving more than 60 countries and regions.

Our factory area( ㎡ )

More than 120 workers

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Daswell will serve you wholeheartedly.