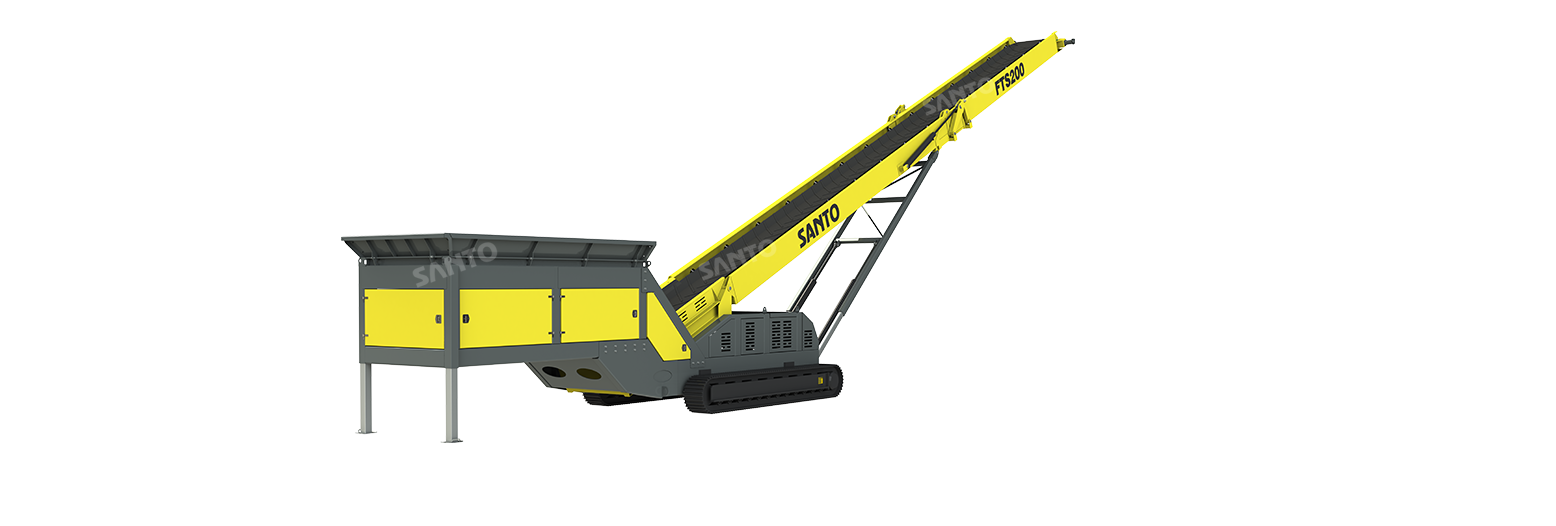

Designed for customers who either require a controlled flow of material output or need to directly feed material using an excavator or wheel loader, mobile hopper feeders can stably feed other conveying equipment, stacking equipment or other equipment. Santo feeder track stackers can regulate the flow of material ensuring it is the perfect partner for barge, train or truck loading or to feed crushers and screeners.

A wide range of hopper options and capacities are available to suit the needs of all types of wheel loaders/grab cranes/excavators.

Hydraulic folding allows the mobile conveyor to fit into 40ft containers for easy, cost effective transport around the globe.

The use of hybrid technology includes an onboard electric motor that provides the flexibility to run the equipment from an external power source or the standard onboard engine.

Track frame - heavy duty tracks suitable for any environment.

A wide range of hopper options and capacities are available to suit the needs of all types of wheel loaders/grab cranes/excavators.

Hydraulic folding allows the mobile conveyor to fit into 40ft containers for easy, cost effective transport around the globe.

Track frame - heavy duty tracks suitable for any environment.

Complete range of mobility and sizes available for a range of applications.

Variable speed belt feeder to ensure efficient material transfer from hopper to discharge conveyor.

Huge stockpiling capacity in its class rates from 100 -1000 tons per hour.

Eliminate double handling of material with wheel loader.

Our tracked feeder conveyors are mainly used to handle bulk materials, you can apply it in multiple fields:

|

Model |

Belt Width (mm) |

Length (m) |

Discharging Height (m) |

Stockpile Volume (m3) |

Capacity (T/H) |

Weight(T) |

|

FTS1015 |

1000 (39.3inch) |

15 (49.2ft) |

7.0 (22.9ft) |

559.6 |

500 |

15 |

|

FTS1020 |

1000 (39.3inch) |

20(65.6ft) |

8.9(29.2ft) |

1181.2 |

500 |

16 |

|

FTS1215 |

1200 (47.2inch) |

15 (49.2ft) |

7.2 (22.9ft) |

559.6 |

700 |

19 |

|

FTS1220 |

1200 (47.2inch) |

20 (65.6ft) |

8.9(29.2ft) |

1181.2 |

700 |

20 |

Our factory area( ㎡ )

More than 30 R&D and design engineers

More than 120 workers

Serving more than 60 countries and regions.

Our factory area( ㎡ )

More than 30 R&D and design engineers

More than 120 workers

Serving more than 60 countries and regions.

Our factory area( ㎡ )

More than 120 workers

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Daswell will serve you wholeheartedly.