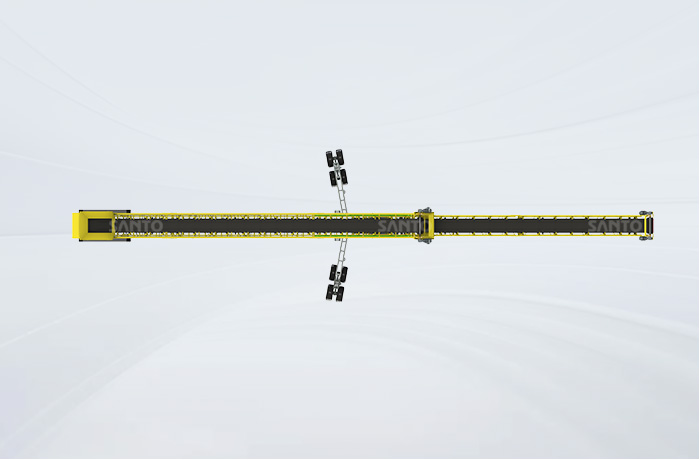

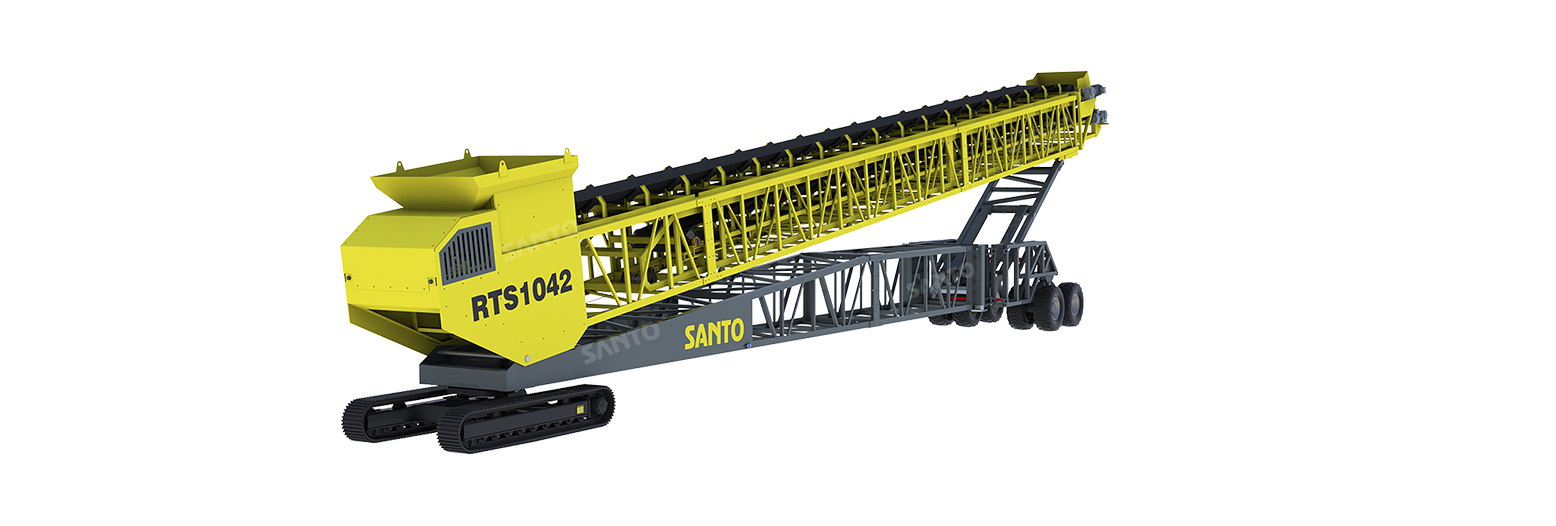

Radial telescopic conveyor is also called mobile telescopic stacker. By adding telescopic conveyor and automatic lifting frame, the stacking radius and height can be easily adjusted, and circular rotation can be realized under the condition of fixed turning point and rotating track tire or track. It is especially suitable for material stacking of large construction aggregate production line and mineral processing production line. Santo mobile radial telescopic conveyor is one of the most cost efficient and effective ways of stockpiling material on the market.

The belt conveyor can be telescopic and retractable, and the up and down angles can be pitched.

The engine drives the track chassis and can remote control walking.

The wheel-side hydraulic motor reducer drives the tires to realize the radial rotation of the belt conveyor.

The belt conveyor can be telescopic and retractable, and the up and down angles can be pitched.

The engine drives the track chassis and can remote control walking.

The wheel-side hydraulic motor reducer drives the tires to realize the radial rotation of the belt conveyor.

Easily utilized in fixed and mobile crushing and screening operations.

With their rapid deployment capabilities and high stacking capacities, telescopic stackers enable faster material handling operations, reducing downtime and increasing overall productivity.

30% more stockpile capacity on same footprint when comparing standard conveyors.

Optional feed boot extensions, wear liners, rock shelf and impact solutions available.

They can handle a wide range of materials, from aggregates to bulk solids with ease.

|

Model |

Belt Width (mm) |

Length (m) |

Discharging Height (m) |

Stockpile Volume (m3) |

Capacity (T/H) |

Weight(T) |

|

RTS1042 |

1000 (39.3inch) |

42 (137.8ft) |

14.5 (47.5ft) |

5336.4 |

500 |

38 |

|

RTS1242 |

1200 (47.2inch) |

42 (137.8ft) |

14.5 (47.5ft) |

5336.4 |

700 |

48 |

Our factory area( ㎡ )

More than 30 R&D and design engineers

More than 120 workers

Serving more than 60 countries and regions.

Our factory area( ㎡ )

More than 30 R&D and design engineers

More than 120 workers

Serving more than 60 countries and regions.

Our factory area( ㎡ )

More than 120 workers

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.

You can contact us by filling in the information below, the official service consultant will contact you within 12 hours, please keep the phone open. If you have any questions or suggestions, please fill in the following form, Daswell will serve you wholeheartedly.